Dustless Blasting Equipment

At Hodge Clemco we offer various solutions for dustless blasting equipment. The combination of our standard portable blast cleaning equipment and our abrasive recovery system creates an effective and efficient close circuit dustless blasting system. Our Eductoblast is air powered and ideally suited for use with recyclable abrasives. A smaller closed circuit suction unit, the Eductomatic, is available where portability is the primary selection criteria. All closed circuit blasting units collect the spent material, remove any contamination and feed clean recycled grit back to the blast nozzle. Closed circuit blast machines are used on applications where dustless blasting and containing the airborne abrasive and dust is essential, especially in areas where other personnel are working. These machines provide a low cost and efficient means for in-situ dustless blasting.

Hodge Vac

The Hodge Vac includes all the tools and fittings you need to convert any Hodge Clemco standard blast machine to a closed circuit abrasive recovery dustless blasting system within seconds. Closed circuit blasting uses a combined blast and vacuum head which allows the operator to blast without the need to encapsulate the area or wear the PPE normally used for blasting.

All pressure blast machines manufactured by Hodge Clemco can be adapted to use a closed circuit blast head. Our Aquagrit WDOS (dry), 1028NC and 1440NC blast machines are ideally suited, due to their portability.

The key to an efficient closed circuit system is the vacuum unit used. The Hodge Vac uses a purpose designed jet system which is pneumatically driven and also available to ATEX standards and HEPA filtered as options. The Hodge Vac silo has the same abrasive capacity as a 2040NC blast machine.

Operating on a recover to waste principle, this makes it effective and portable and the ideal tool for spot repair work where encapsulation is expensive or ineffective. All recovered waste is discharged into a waste bag, which can be sealed and removed minimising the exposure to the operator from contaminated waste.

Eductomatic

When containment of dust and abrasive is necessary, the Eductomatic is an essential tool. A range of heads are available to provide a seal against most surfaces. A 360° swivel blast head enables cleaning at all angles and with a total weight of 3 kg it is light and manoeuvrable. Air volumes of 33-60 cfm at 90 p.s.i, are required to power the unit. Abrasive will normally be of a recyclable type which is cleaned by the unit with all dust contained in an attached dust bag or for production use in a separate dust collector. With easy filling and a blast pattern of approximately 32mm diameter the Eductomatic is a clean and simple unit to operate, ideal for those difficult areas.

When containment of dust and abrasive is necessary, the Eductomatic is an essential tool. A range of heads are available to provide a seal against most surfaces. A 360° swivel blast head enables cleaning at all angles and with a total weight of 3 kg it is light and manoeuvrable. Air volumes of 33-60 cfm at 90 p.s.i, are required to power the unit. Abrasive will normally be of a recyclable type which is cleaned by the unit with all dust contained in an attached dust bag or for production use in a separate dust collector. With easy filling and a blast pattern of approximately 32mm diameter the Eductomatic is a clean and simple unit to operate, ideal for those difficult areas.

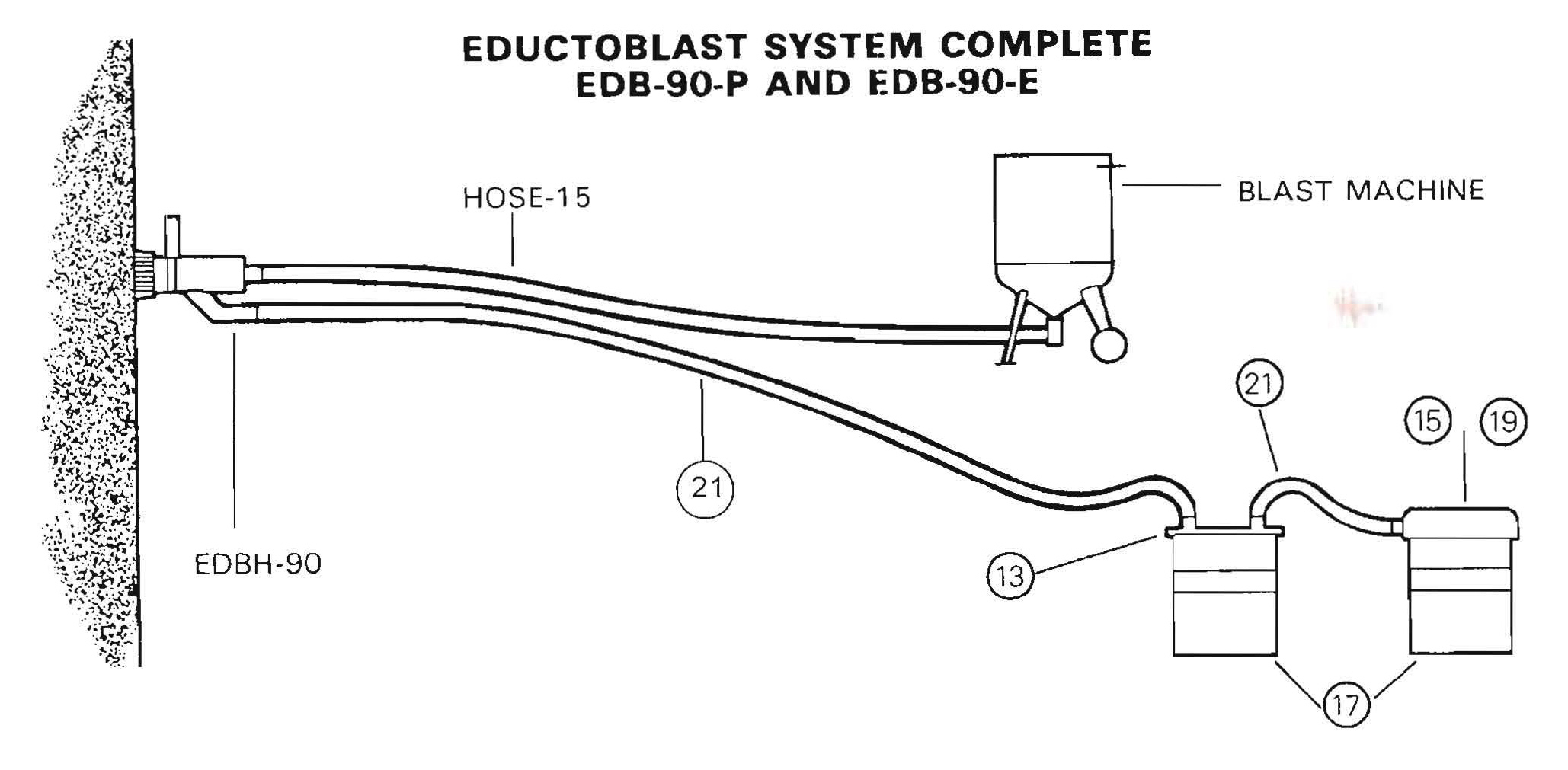

Eductoblast

By combining Hodge Clemco’s standard portable blast cleaning equipment and abrasive recovery system, an effective and efficient closed circuit blast system has been developed. The Eductoblast is an air powered unit and is ideally suited for use with metallic abrasives. For other commonly used abrasives the addition of a spent material collection hopper is recommended. This collection hopper is particularly useful for safe disposal of lead based coatings. There are 2 models in the range, the EDB 60 and the EDB 75.

By combining Hodge Clemco’s standard portable blast cleaning equipment and abrasive recovery system, an effective and efficient closed circuit blast system has been developed. The Eductoblast is an air powered unit and is ideally suited for use with metallic abrasives. For other commonly used abrasives the addition of a spent material collection hopper is recommended. This collection hopper is particularly useful for safe disposal of lead based coatings. There are 2 models in the range, the EDB 60 and the EDB 75.

Twin Outlet Trolley-Mounted Closed Circuit Dustless Blasting Machine

- Ideal for when two operators are required. (Can also be used with one operator).

- To be used with recyclable abrasives.

- Ideal for when dust or abrasive is not permitted on site.

- Perfect when a controlled blasting area is required.

- Remote operated air & grit valves are fitted to give each operator separate control of the machine.

- Automatic units can be made to your own specifications.

Manual (255D)

Manual (255D)