Hardness Testing

Hardness testing can be defined as a material’s resistance to indentation.

Testing for harness is an important step in many industries around the world, including metals, fiberglass and plastics, and is often used to certify quality of material, test repairs and protect from coating failures. Both Shore and Barcol scale testers are available.

The Positector SHD measures the hardness of non-metallic materials. Features include user adjustable measurement time with on-screen countdown to conform to international standards, internal memory, on-screen statistics and an electronic ‘maximum’ reading indicator. Available in two ranges – Type A and Type D.

Compatible with – Standard and Advanced body.

Handheld electronic instrument measures the indentation hardness of non-metallic materials. Two durometer models are available for different hardness ranges – Shore A and Shore D.

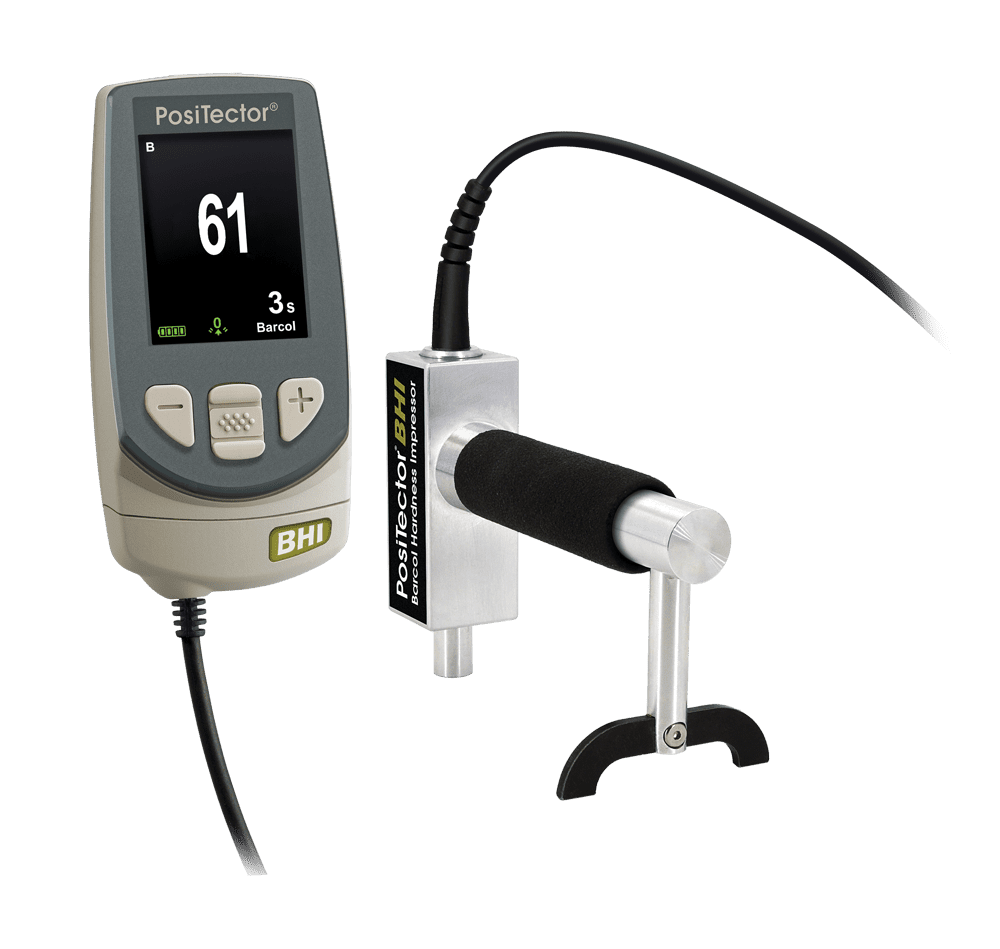

The PosiTector BHI measures the hardness of soft metals such as aluminium, aluminium alloys, copper, brass, and other materials such as harder plastics, and fibre-reinforced plastic.

Compatible with – Standard and Advanced body.

Conforms to ASTM B648/D2583, DIN EN 59 and AS/NZS 3572.22

You can find further information in our Inspection and Testing Equipment brochure.

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.