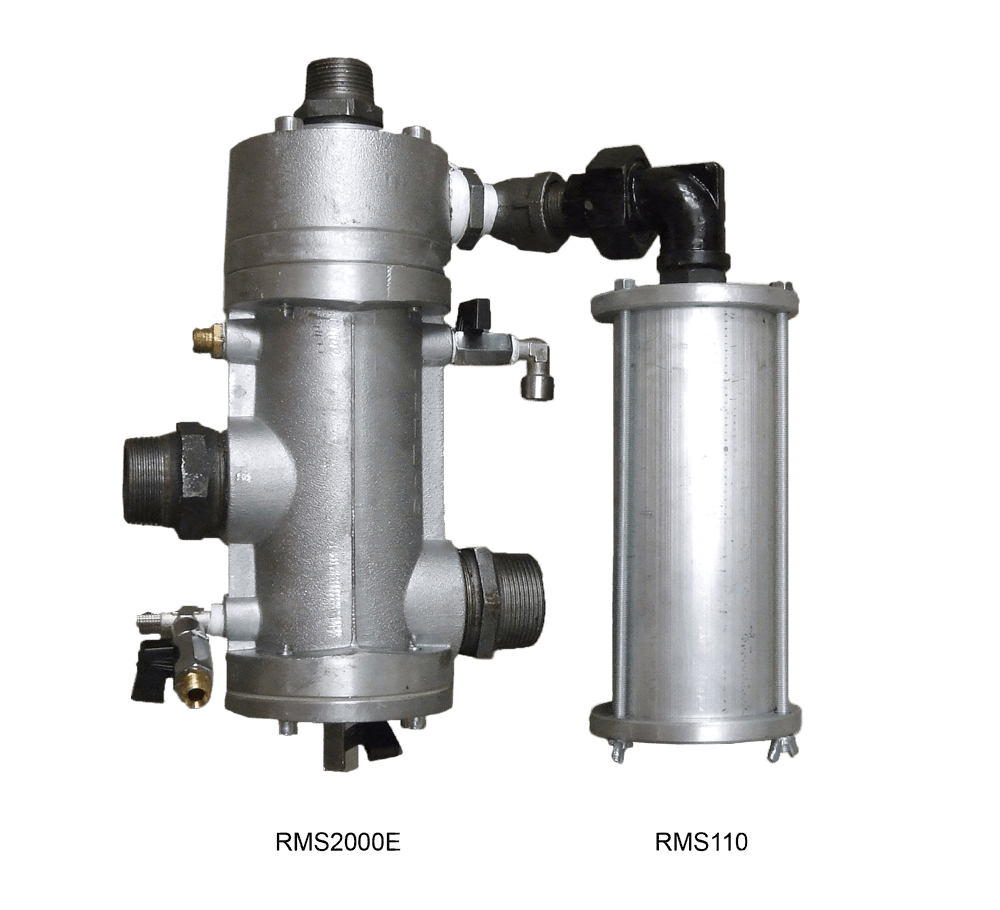

This valve allows the blast machine to be depressurised from a remote deadman handle fitted at the blasting nozzle. This eliminates accidents and reduces wastage. This remote control valve is fitted with 1.1/2″ ports.

The RMS-2000 recova valve incorporates two valves in one body, the lower for compressed air inlet control and the upper for controlling the exhaust outlet of the abrasive blasting machine.

A constant source of compressed air is supplied to the inlet, fitting (R or 1) on the pneumatic deadman handle via a minimum 1/4″ i.d. flexible air hose from the fitting marked ‘1’ on the lower part of the RMS-2000 body. The air supply is returned from the outlet fitting (Y or 2) on the deadman handle to the fitting marked ‘2’ on the upper part of the RMS-2000 body by a second 1/4″ i.d. air hose.

Note: The RMS2000 system can also be controlled by an electric deadman handle.

Activation of the two valves is achieved simultaneously on closing the deadman handle lever. Deactivation takes place immediately on release of the handle or by opening the safety petcock on the RMS-2000 valve body.(Opposite port numbered ‘2’)

It is a feature of this system that the air exhausted from the abrasive blast cleaning machine does not pass through the working parts of the valve, thus any wear caused by airborne particles of abrasive is restricted to the rubber diaphragm (RMS-2004).

The valve is designed for easy maintenance with the use of only a few tools.

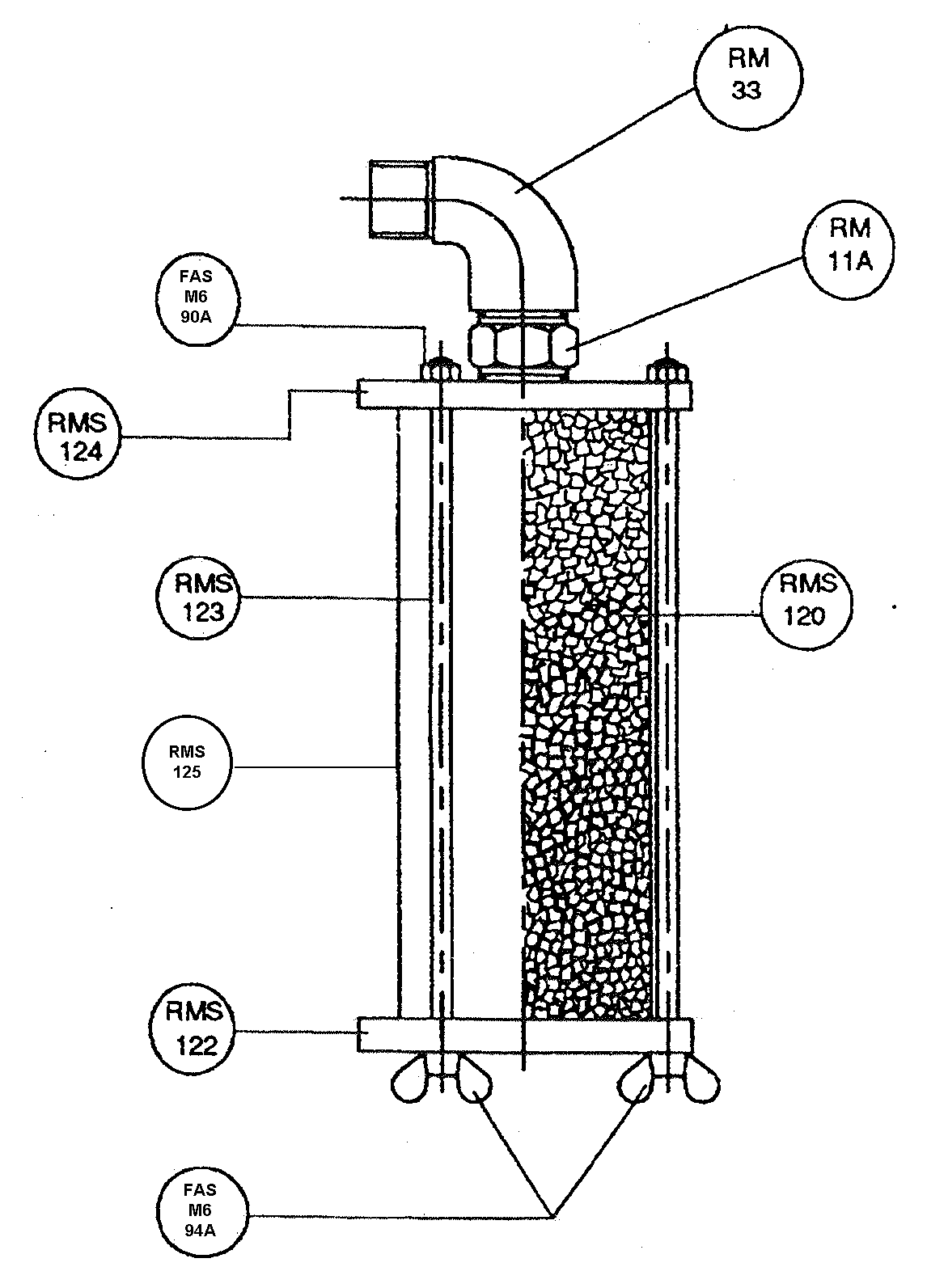

| SILENCER REPLACEMENTS PARTS | |

| RMS 120 | CORE |

| FAS M6 90A | NUT |

| FAS M6 94A | WING NUT |

| RMS 122 | BOTTOM COVER |

| RMS 123 | STUD BOLT |

| RMS 124 | TOP COVER |

| RMS 125 | BODY |

| RM 11A | 3/4″ NIPPLE |

| RM 33 | 3/4″ M/F ELBOW |

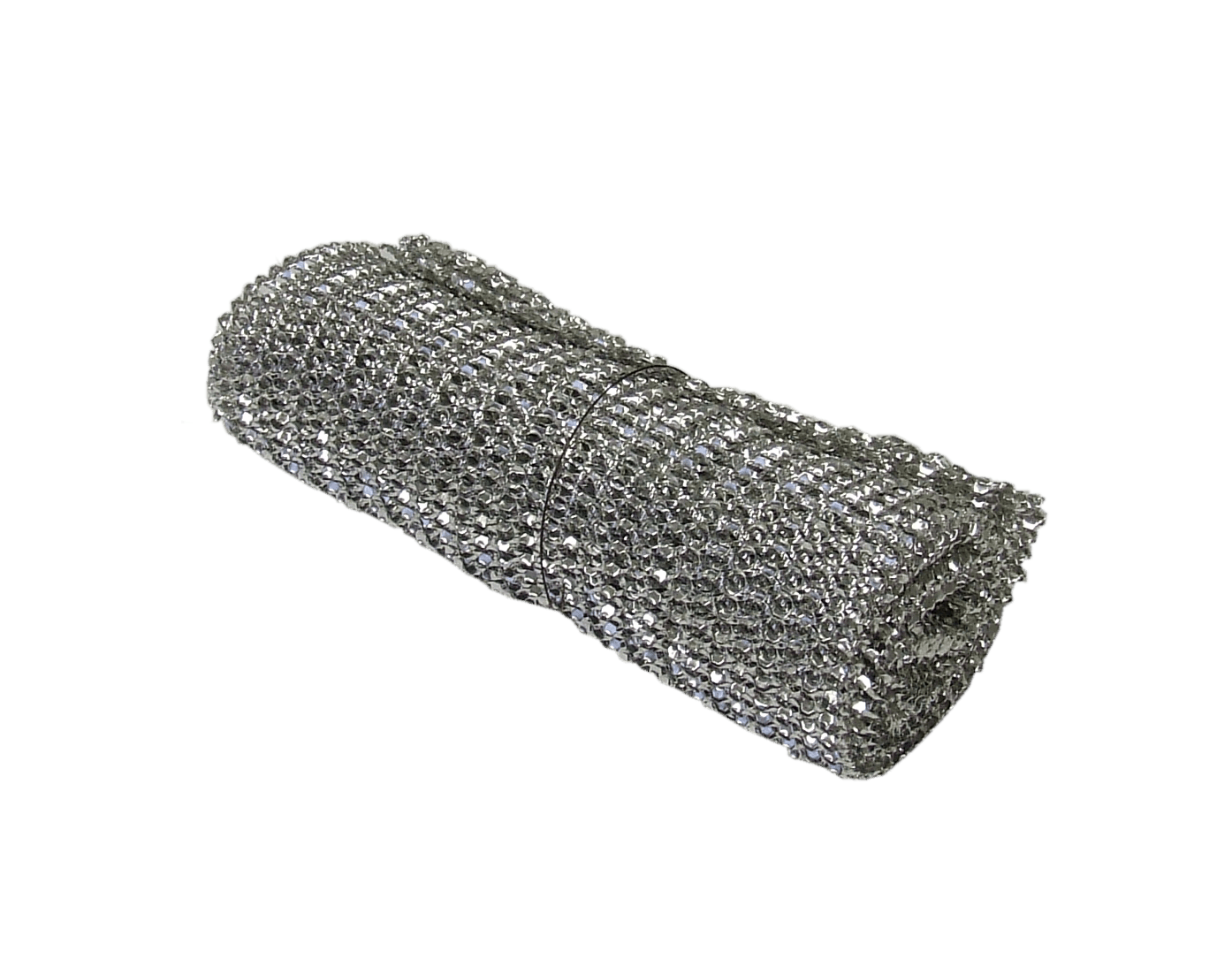

Silencer Core (RMS120)

Replacement filter material for the RMS110 Silencer, maintains exhaust emissions within limits defined by the Health & Safety Executive.

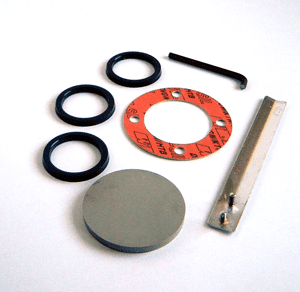

Repair Kit (RMS2000RK)

Repair kit for the RMS2000 remote control valve. Kits contain all seals required to maintain remote control valve efficiency.