Dust Extraction

Choice of the correct model of dust collector is essential for any closed blasting system. The removal of airborne particles from the environment of a blast chamber is essential to maintain efficient operation. Savings made by cutting cost at this point will only lead to reduced efficiency, early failure of the system and higher running costs.

Factors to consider whilst choosing a dust collector are:

- Correct air speed through the blast room prevents settlement of airborne particles in the work area.

- The direction in which the air flows through the blast room is critical to the process. Correctly sized and positioned air inlets and extraction duct work ensure that first class ventilation is achieved.

- The filtration area is the surface area of the filter material within the dust collector. It is essential that the ratio between filtration area and air volume is correct to prevent premature failure of the extraction system.

Reverse Pulse Dust Collectors

Reverse pulse dust collectors use filter cartridges which are cleaned whilst the collector is in operation ensuring the efficiency of the collector is maintained. A short pulse of air causes the dust accumulated on the cartridges to fall into collection bins below at pre-determined intervals keeping the cartridges clean whilst the collector is in operation. Reverse pulse dust collectors can be used with high specification filters on hazardous dust applications and can be operated in conjunction with secondary or HEPA filters for increased efficiency.

Reverse pulse dust collectors use filter cartridges which are cleaned whilst the collector is in operation ensuring the efficiency of the collector is maintained. A short pulse of air causes the dust accumulated on the cartridges to fall into collection bins below at pre-determined intervals keeping the cartridges clean whilst the collector is in operation. Reverse pulse dust collectors can be used with high specification filters on hazardous dust applications and can be operated in conjunction with secondary or HEPA filters for increased efficiency.

Animated video of reverse pulse dust collector

Manuals:

MJC Cartridge Filter Unit – OPERATION & MAINTENANCE (Manual 536.1a)

MJC Cartridge Filter Units – INSTALLATION (Manual 536.2)

Reverse Pulse Cartridge Collectors (Manual 396)

Airmaster MJC Mini Dust Collector (Manual 556)

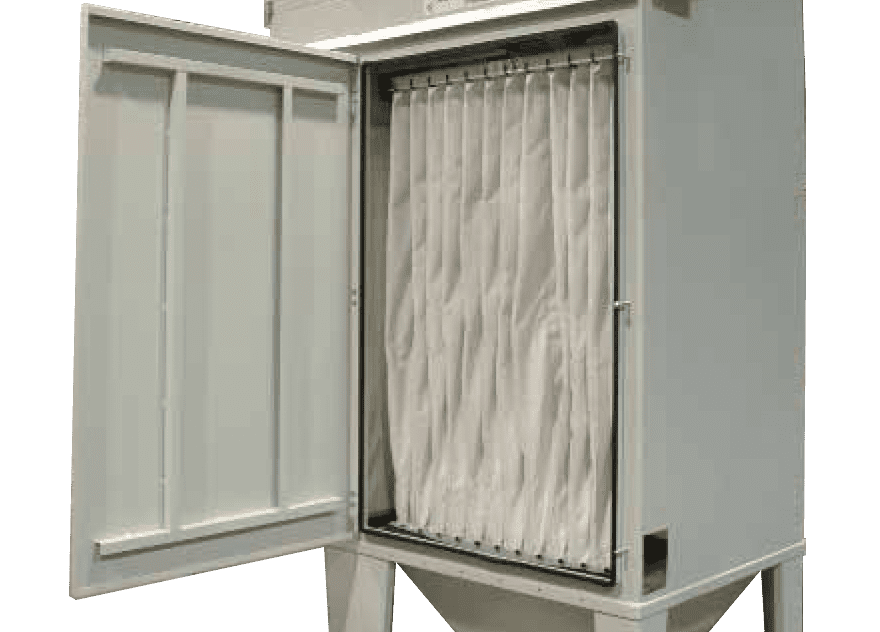

Bag Filter Dust Collectors

Bag type dust collectors use pocket bag filters to remove any airborne dust from the system. The retained dust is removed from the filter bag by a short vibration cycle where all material is dislodged which falls into the collection bin. The shake cycle is carried out automatically when the unit is powered down at the end of the shift. Different types of filter material are available for a wide range of applications. The efficiency of our units exceed the requirements of both the EPA and COSHH legislation. The key to low running costs is the extra filter material we use in our collectors which extends the life of the filter and increases the visiblity in your shot blast booth.

Manuals:

Auto MZ filter units (Manual 535)

Portable Site Dust Collectors

Our portable range of site dust collectors use a principle of operation identical to our reverse pulse dust collectors. They differ from our portable range as they are designed specifically for robust handling on site. The low centre of gravity prevents accidents during movement around site and damage from high winds. These portable units make them ideal for use on bridge maintenance contracts and in shipyard environments. The units are available with secondary HEPA filtration on applications where the hazardous nature of the coating is unknown. Our unit is available rated at 8000 cfm and is fitted with two 14″ diameter inlet spigots.

Our portable range of site dust collectors use a principle of operation identical to our reverse pulse dust collectors. They differ from our portable range as they are designed specifically for robust handling on site. The low centre of gravity prevents accidents during movement around site and damage from high winds. These portable units make them ideal for use on bridge maintenance contracts and in shipyard environments. The units are available with secondary HEPA filtration on applications where the hazardous nature of the coating is unknown. Our unit is available rated at 8000 cfm and is fitted with two 14″ diameter inlet spigots.

Ducting

Efficient airflow is key to improving visibility inside a blastroom enclosure. Correct ducting design is equally as important as the dust collection equipment. The use of suitably sized and positioned air inlet ducts allows for a laminar airflow down the booth which ensures that the dust is conveyed to the dust collection plant. Incorrect duct design means that air will stagnate in the blastroom resulting in poor visibility and longer cleaning times. Hodge Clemco incorporates spiral wound ducting, purpose designed for each application. Seamless, flanged and welded ducting is also available on hazardous applications. All Hodge Clemco installations are LEV checked to ensure they conform to the design parameters.

Efficient airflow is key to improving visibility inside a blastroom enclosure. Correct ducting design is equally as important as the dust collection equipment. The use of suitably sized and positioned air inlet ducts allows for a laminar airflow down the booth which ensures that the dust is conveyed to the dust collection plant. Incorrect duct design means that air will stagnate in the blastroom resulting in poor visibility and longer cleaning times. Hodge Clemco incorporates spiral wound ducting, purpose designed for each application. Seamless, flanged and welded ducting is also available on hazardous applications. All Hodge Clemco installations are LEV checked to ensure they conform to the design parameters.

See also:

Blast Rooms

Visit our YouTube channel to see out product videos.