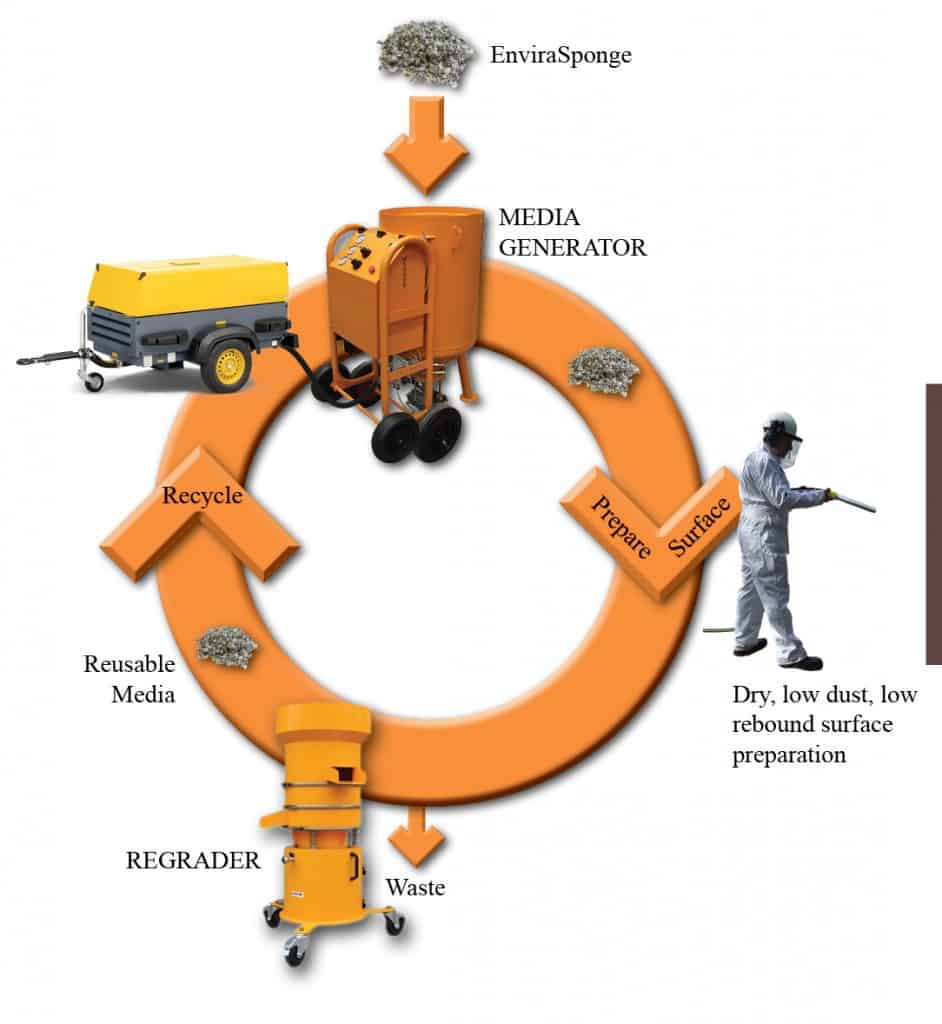

EnviraSponge – Regrader

EnviraSponge regraders are highly mobile and are available pneumatic or electric powered.

They are designed to efficiently reduce sponge media consumption by separating good reusable media from dust, contaminants, oversize particles and other potentially harmful waste which might otherwise become airborne dust.

By reusing sponge media between 6 to 10 times, abrasive costs such as transport, handling, clean-up and disposal are considerably reduced by as much as 90%.

For more information on our EnviraSponge media generators

More information on our EnviraSponge abrasive

Abrasive Media

- It is a low dust media, where contaminants are contained at the source. This results in less dust to collect and a reduced need for dust suppression and extraction

- The media produces superior surface preparation in confined environments.

- An abrasive media that is recyclable and uses dry surface preparation.

- Reduces downtime that means other trades can work simultaneously.

- There is no need to rinse before re-blasting.

- Replaces mechanical cleaning tools for faster and easier treatment of curved surfaces with a near perfect finish.

- Creates a surface profile of 5 – 100 microns on steel.

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.