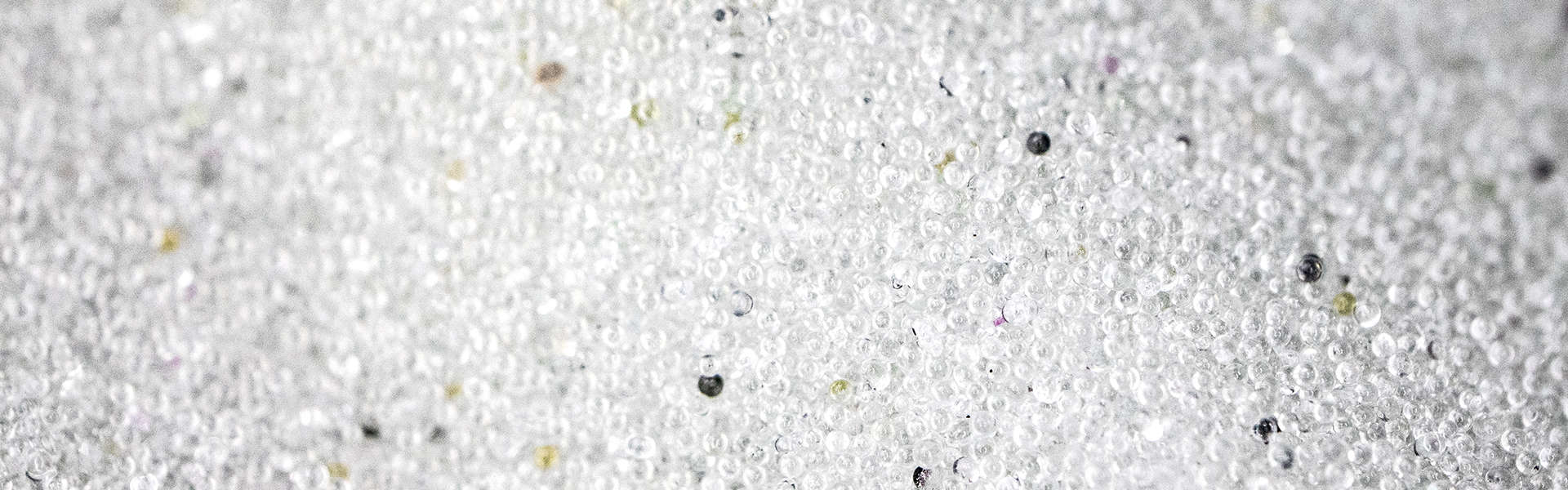

Glass Bead

Glass bead is high-grade soda lime glass bead manufactured by the process of cascading a granulated soda lime glass powder or grain into a vertical kiln and then using the effect of softening the glass and gravity to cause the rounding of the glass grit or cullet. This technique has been refined to produce a sphere that is almost perfectly round, and in the reflective product, produces a prism that can have refractive indices as high as 2. Available in commercial, premium AMS and military specifications, conforming to AMS2431/6C and MIL-9954.

This media is also referred to as Beadomac.

PROPERTIES

Abrasive Type

Density

2.55 g/cm³

Bulk Density

1.5 g/cm³

Hardness

5.0 Mohs

Friability

Recyclability

Dust Levels

Shape

GRADES

Commercial

Product Code – Generic Size (Microns)

GBBT3 0.590-0.840

GBBT4 0.420-0.590

GBBOL21 0.250-0.420

GBBOL23 0.177-0.297

GBBOL24 0.149-0.250

GBBOL25 0.105-0.210

GBBOL26 0.074-0.149

GBBOL27 0.053-0.105

GBBT13 0.044-0.088

GBBOL30 0.030-0.062

Aerospace Castings

Alloy Wheel Repair and Refurbishment

Anti Skid / Road Maintenance

Anti Slip Floors / Safety Flooring

Anti Slip Resins and Paints

Automotive

Bead Blasting

Castings and Forgings

Coatings/Paints/Resins

Glass & Ceramics: Paint & print removal without damage

Metals: Aerospace approval

Metals: Cleaning without dimensional change

Metals: Flash removal

Metals: Keying surfaces for rubber/plastic bonding

Metals: Light deburring

Metals: Peening

Metals: Removal of hard deposits/investment

Metals: Matt or textured finish

Metals: Mould die and tool cleaning

Metals: Preconditioning and cleaning

Metals: Preparation for paint metal or plastic spraying

Metals: Preparation for enamelling/electroplating/anodising

Metals: Removal of paint/scale/rust

Metals: Removal of solder/weld/flex

Metals: Sheen finishing or anti-reflective treatment

Nuclear and Power Generation

Oil and Gas Industries

Open Nozzle Blasting

Peening

Plastics & Composites: Removal of paint and coating

Polishing

Road Marking and Reflective Media

Shot Peening

Surface Finishing

Vapour blasting / Wet blasting

Vehicles

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.