Foundry & Forge

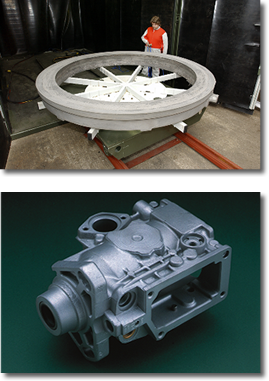

Foundry & forge applications typify heavy engineering. The harsh environments of traditional foundries are nowadays contrasted by hi-tec lost wax and die-casting applications.

Hodge Clemco has provided solutions to these industries for decades. Our range of blast rooms is well suited to these environments due to the heavy nature of the construction.

The efficiency of the recovery systems and our air wash unit is sufficient to remove foundry sand, runners, risers and tramp from the useful abrasive mix. Forge scale is easily removed from media and is separated into the scalping drum.

Our range of cabinets is able to process delicate die castings, using a variety of materials such as Aluminium Oxide and Glass Bead. Hodge Clemco systems can be used for de-flashing components or to provide a cosmetic finish.

For more information on our full range of blast cabinets, view our blast cabinet brochure.

Shot blasting cabinets for all your blasting needs are available from Hodge Clemco.

We are able to provide pressure blast cabinets suitable removing heavy corrosion and tough coatings. They are also great when high production rates are necessary.

Our suction cabinets are a great choice for use when ensuring a decorative or aesthetic finish on a variety of materials.

We also offer automated blast cabinets and stock a range of spares and parts for the machines.

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.