Automated Blast Cabinets

At Hodge Clemco we offer a range of automated blast cabinets.

To order or for further info please contact our sales team.

Indexing Table machine (A200)

At Hodge Clemco or range of automated equipment includes an indexing machine designed for high production output.

Our A200 model can be fitted with 6, 8 or 12 satellite tables. These can be fitted with fixtures to hold products from 150mm diameter x 300mm high.

The operator loads the products onto the turntable from the front opening door. The operator also offloads the components from this location.

The multiple blast guns are located on adjustable arms so they can be positioned to suit a wide range of product types. Reciprocators can also be fitted to manipulate the guns in front of the rotating satellite tables. This gives better cleaning results on awkward or difficult to clean products.

The heavy duty nature of this machine allows it to be operated with a wide range of abrasives. This allows production to be further increased by utilising a pick and place robot for loading/offloading operations.

Rotary Table with Recipricator

Our blast cabinets can be adapted for use with manual or powered turn-tables. However, in the case of powered turn-tables, they can be operated in conjunction with reciprocators. When operated together, the rotary action and linear motion make them ideal prospects for blasting the internal or external faces of cylinders.

The machine showed in the photograph is designed for cleaning the internal faces of aero engine mounting discs. These are stacked on top of each other forming a cylinder. Aluminium Oxide is used to provide a uniform and coarse etch prior to applying a metal sprayed coating.

The controls allow the rotation speed, reciprocation length and stroke to be altered. This allows the unit to operate without user intervention. This machine also has a feature enabling it to be operated manually.

Tumbleblast Cabinet

(Batchmaster Cabinet)

The addition of a tumble basket to any blast cabinet, enables batches of small products such as nuts, bolts or washers to be processed automatically.

The parts are loaded into the basket and the products rotate inside. The basket has a gentle tumbling action. This ensures all the complex faces of the products are exposed to the blast gun giving a uniform blast finish.

Tumble baskets are available as a retrofit or purpose built. This is done to suit the application. Fully automated and semi-automated tumble blast cabinets are available. These can quickly be converted back to a manual system offering a flexible solution.

Belt Conveyor Machine

The design premise behind this belt conveyor machine is continuous operation. And with a single operator facility. The operator loads small castings onto the inlet end of the belt. This then conveys the products through a sealing vestibule past a range of suction guns. These remove any burrs on the castings and provide an aesthetic finish.

The abrasive used in this application is glass bead. This is matched in size to suit the finish required on the magnesium castings. The clean components are blown down to remove any residual abrasive. The products are thendischarged onto a cross feed conveyor. They then go back to the front of the machine for offloading and packaging.

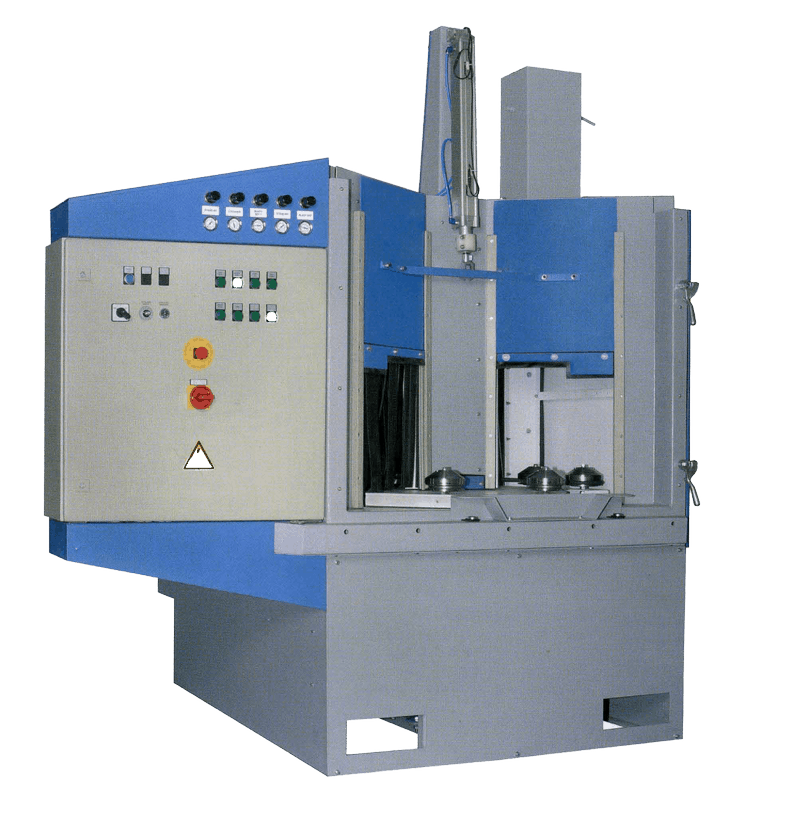

Internal Cylinder Cleaning

Hodge Clemco purpose-designed and manufactured an internal cylinder cleaning. The machine was for the leading manufacturer of aluminium gas bottles in the UK.

The machine was designed to be both simple to operate and easy to maintain. The use of agency staff by the client dictated, that the control system needed to be intuitive. The PLC control system enabled the operator to select from a list of preset part numbers. Then the machine automatically set the required parameters. This machine allowed the components to be processed from: 90mm ID to 230mm OD and from 300mm to 1830mm long.

The internal walls of the bottles are cleaned by a lance. This is automatically fed from the base of the machine, through the neck and into the bottle. The abrasive in this application was glass bead. This not only removed the score marks from the previous drawing operation but, also peened the internal surfaces, increasing the fatigue life of the parts.

See Also:

Blast Cabinets Brochure

Customer Stories

Consumables/Spares

Cabinet Spares

Cabinet Accessories