Inspection

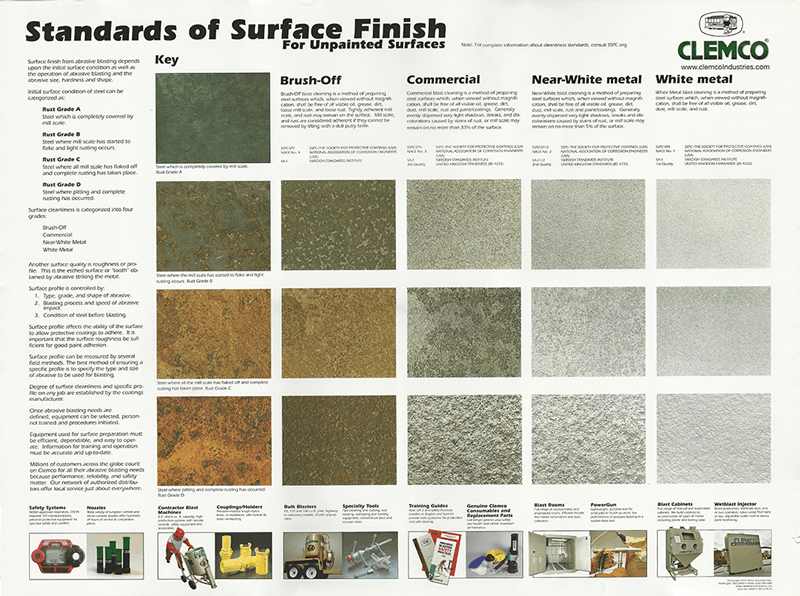

Inspection testing is important in the testing of surface finishes.

At Hodge Clemco we supply equipment for testing the surface properties of materials.

We supply equipment that can help you test the surface for

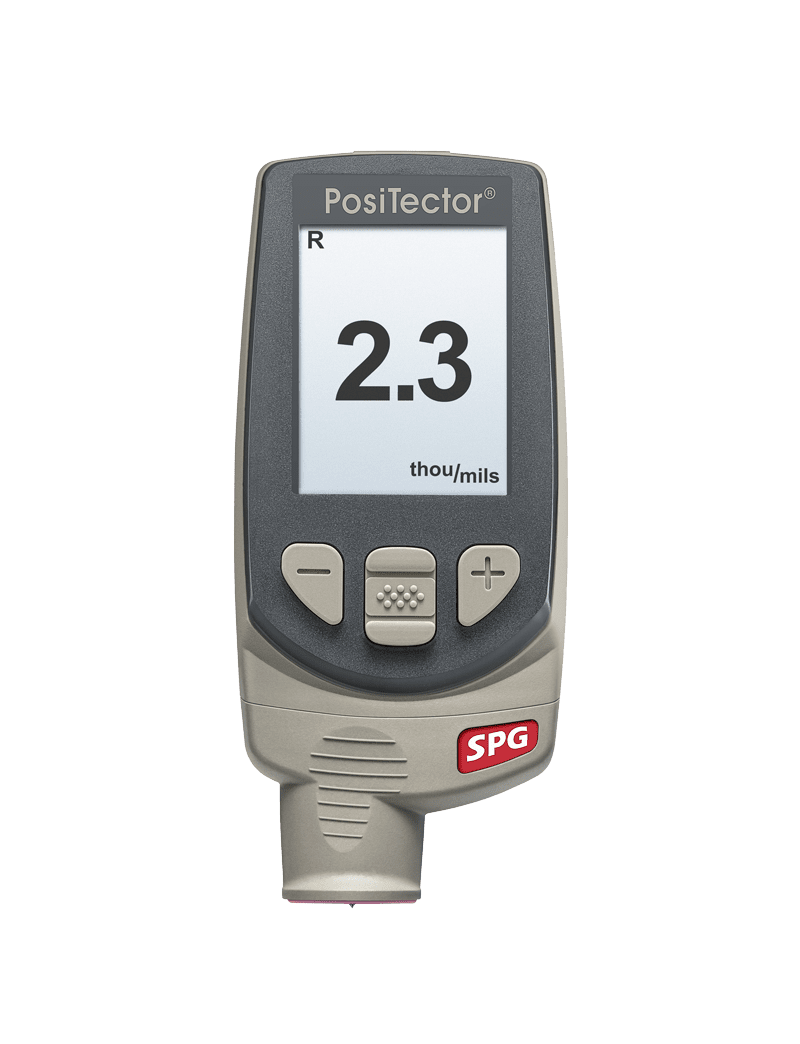

Surface Profile

Steel tends to be abrasive-blast cleaned or roughened prior to painting. The peak-to-valley height of the resultant “surface profile” is important and a determining factor in the performance of applied paint or protective coatings. A surface profile height that is low may reduce coating adhesion. Too high and the peaks may receive insufficient coverage that leads to premature rusting. It can often require additional paint to cover the anchor profile.

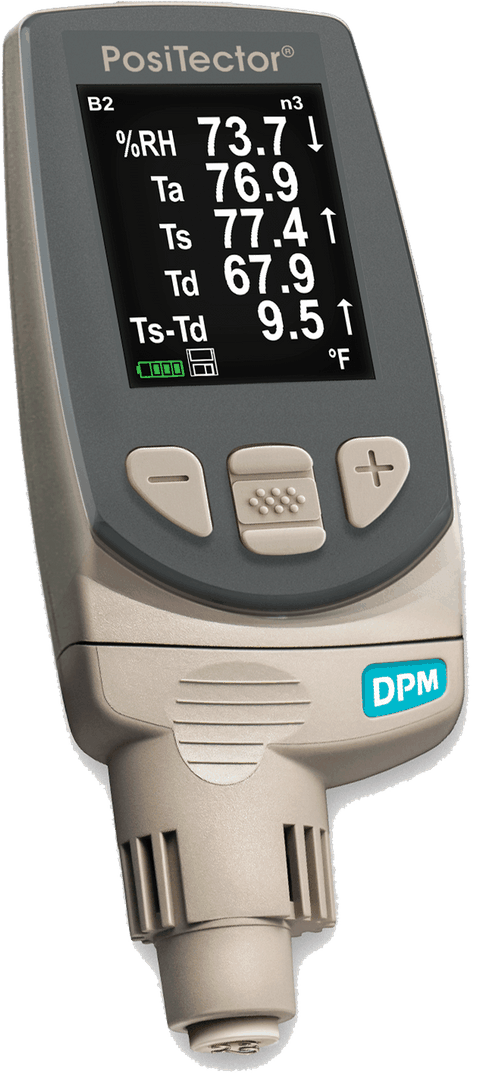

Environmental Conditions

Pre-treatment and application of a coating system are major factors affecting the long-term performance of coatings on steel structures this is affected by environmental conditions.. This can be measured with Dew Point Meters before, during, and after painting. Ideal for surface preparation as required by ISO 8502-4.

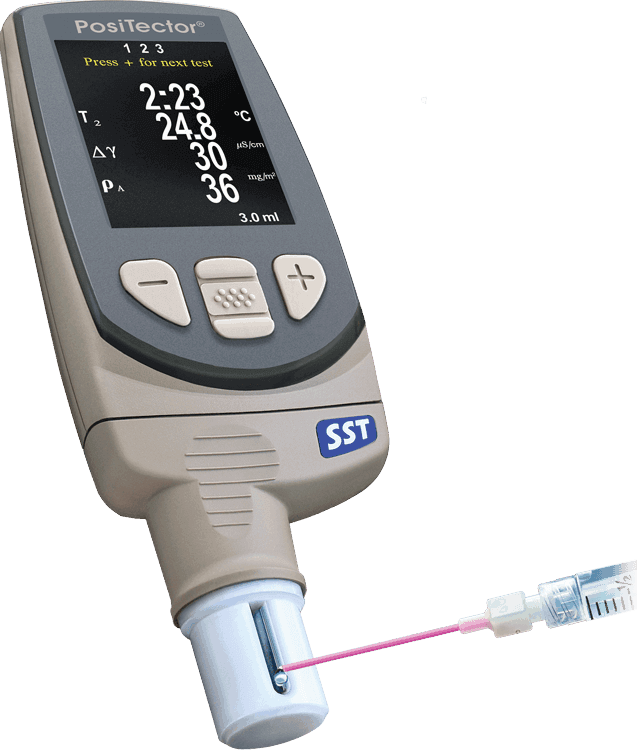

Salt Contamination

Soluble salt testers measure the concentration of soluble salts other wise known as salt contamination on the surface of metals in accordance with ISO 8502-6, 8502-9.

Coating Thickness

Also referred to as paint thickness, or dry film thickness (DFT) is an important variable. It has an impact on product quality, process control, and cost control. The measurement of film thickness can be accomplished by selecting the best mil gauge for the application you are undertaking.

Pinhole/Porosity

Pinhole testing is performed with a variety of equipment designed to pass an electrical charge over a paint or coating system. It detects flaws and defects.

Wall Thickness

Ultrasonic Wall Thickness Gauges measure the wall thickness of materials. Ultrasonic Thickness Gauges are ideal for measuring the effects of corrosion or erosion.

Adhesion

The ability for a coating to adhere to a substrate termed as ‘substrate adhesion’ . In can also be used for a coating to adhere to multiple coats. This is called ‘inter-coat adhesion’.

We stock a range of PosiTector products as well as comparators and comb gauges.

You can find further information in our Inspection and Testing Equipment brochure.

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.