Surface Profile

A surface profile is important when working to achieve a surface finish.

Steel is often abrasive blast cleaned prior to painting. The peak-to-valley surface profile height of the resultant profile is an important factor in the performance of applied protective coatings. Low profile may reduce coating bond strength (adhesion). Too high and the peaks may receive insufficient coverage and possibly rust prematurely. Therefore, surface profile should be measured prior to coating application to ensure that it meets contract specifications.

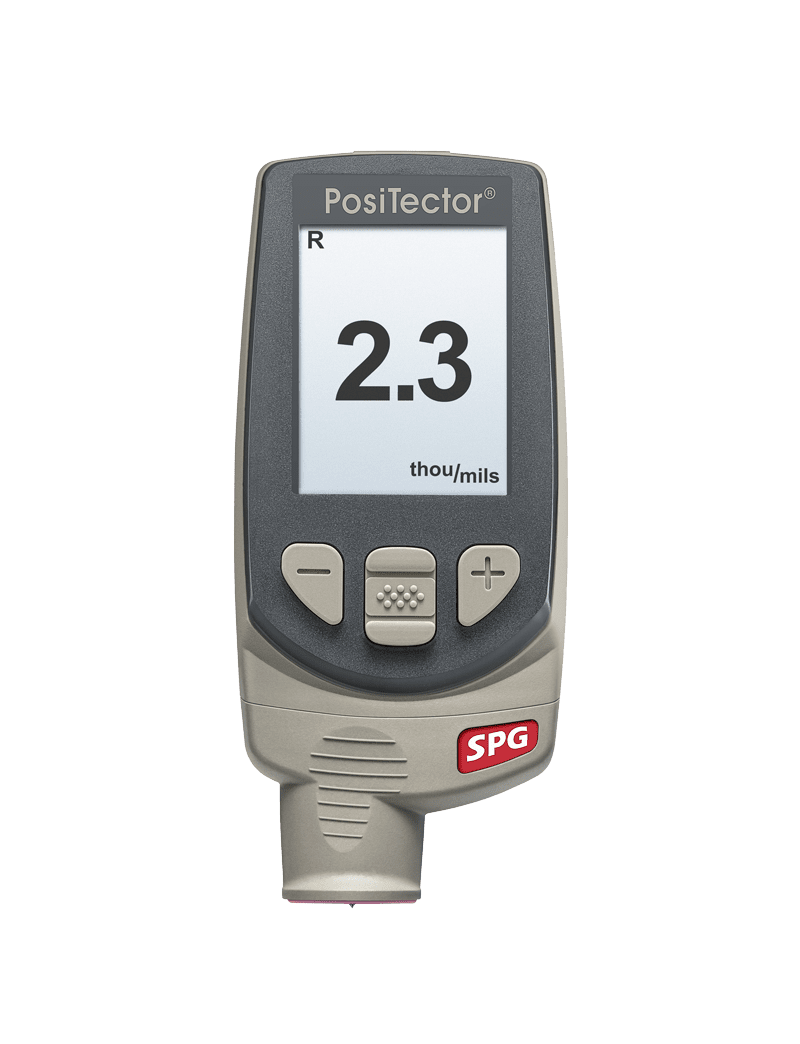

PosiTector SPG – Surface profile gauges measure and record peak to valley profile heights on metal that has been blasted. It can also be used on concrete and textured coatings with a depth micrometer fitted with a fine pointed probe. This gauge includes a more durable alumina wear face and two cabled probe versions. One for measuring the profile of of the textured coatings.

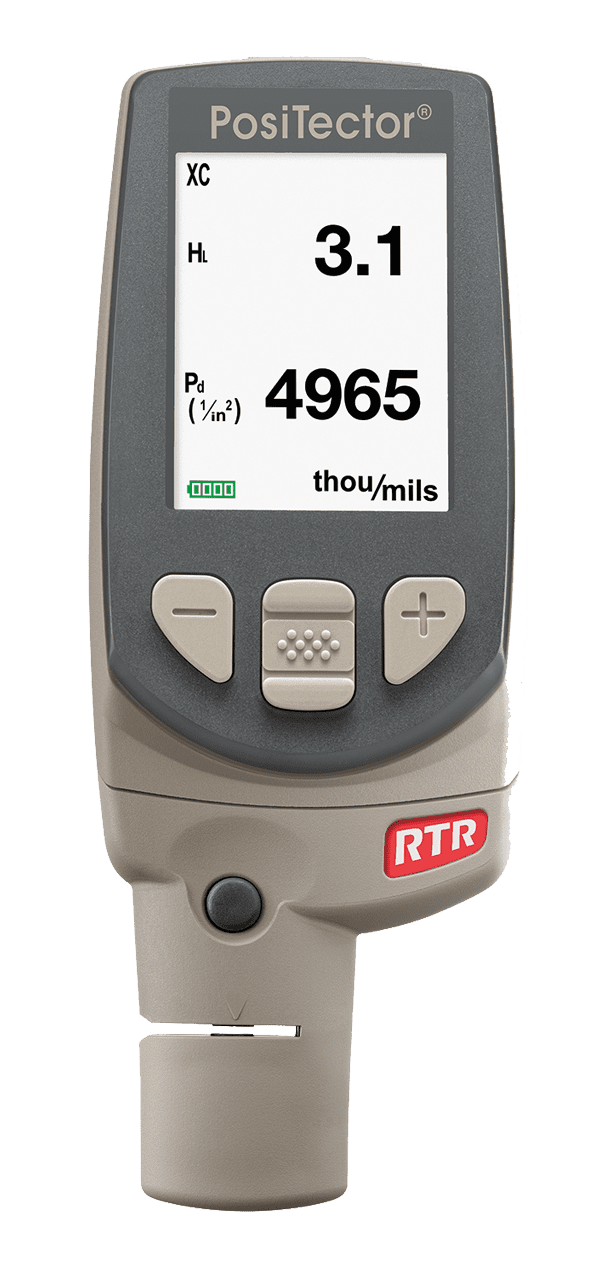

PositTector RTR -Replica tape readers measure and record the profile parameters using replica tape. It digitally measures peak to valley profile height.

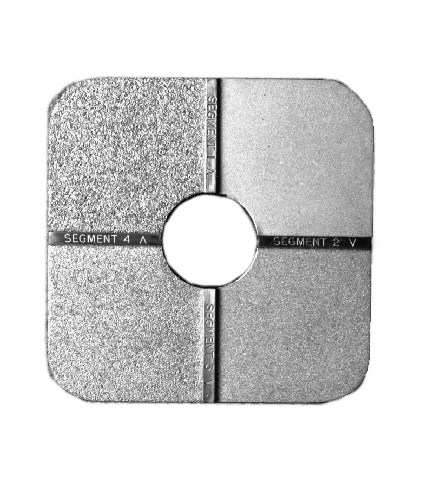

Grit and shot comparator – Visual and tactile guide to surface roughness, ISO 7079. There are four segments each with differing degrees of etch.

You can find further information in our Inspection and Testing Equipment brochure.

For more information on our range of products view our product catalogue.

See the full selection of our abrasive materials in our abrasives brochure.

Watch our product videos on our YouTube channel.